SAFEChecks has helped clients in Los Angeles and throughout the United States prevent check fraud and stay scam-free with our business checks.

The SuperBusinessCheck is one of the most secure checks in the world. Designed by Frank Abagnale with 16 safety features, the check is virtually impossible to replicate or to alter without the fraud becoming evident.

While there are inks with special security features (color-shifting properties, for example), the void pantograph is generally created using prepress software and requires specific line screens.

- Use this high quality blank check stock with your accounting software, laser printer and MICR toner to produce complete checks. Each sheet contains one top check and two stubs. These checks DO NOT include a signature line. Paper Stock: Constructed of 24# paper; Colors Available: Blue/Green, Blue/Burgundy.

- Compatible with most money management software programs. Security features include: Check-21 compliancy, 'VOID' pantograph on the front and back, erasure-resistant background, security warning, anti-splice backer, security features listing, watermark, check verification number, patterned background and microtext print. Gem State Paper.

Our SuperBusinessCheck includes the following check security features:

- Fourdrinier Watermark

- Thermochromatic Ink

- High-resolution Borders

- Microprinting

- Chemical Wash Detection Boxes

- Prismatic Printing

- Laid Lines

- Warning Banner

- Controlled Paper Stock

- Chemically Reactive Paper

- UV Light-Sensitive Ink

- UV Light-Sensitive Fibers

Nationwide Check Security Services

Clients throughout the United States choose SAFEChecks for our check security services. Our checks are fully compatible with today's Check 21 environment (bank imaging). The SuperBusinessCheck has a distinct appearance and combination of safety features which give the greatest deterrence to check fraud. The SuperBusinessCheck is printed on tightly controlled, true-watermarked security paper. For your protection, checks are never sold blank without first being customized for a specific customer. If you are interested in obtaining the Abagnale SuperBusinessCheck, please get in touch with us today!

Customized Controlled Paper Stock

The SuperBusinessCheck is manufactured in the USA with top quality, premium-grade security paper made by Appleton Papers. The check stock is tightly controlled, and no checks are ever sold completely blank. Every check order is customized in some way for the end user. Companies that print their own name, address, MICR line, etc. on their checks still receive some type of customization on the SuperBusinessCheck that is unique to their company.

Fourdrinier Watermark

The SuperBusinessCheck contains a dual-tone Fourdrinier (true) watermark that is pressed into the paper at the mill and is visible from either side when held to the light. This dual-tone true watermark provides instant authenticity of the document and cannot be replicated, copied or scanned.

Thermochromatic Ink

The front of the SuperBusinessCheck contains two pink lock-and-key icons printed with thermochromatic (heat-sensitive) ink that fades away when heated above 85° and reappears when cooled. This thermochromatic icon can be rubbed or breathed on for instant authentication of the check. Color copiers cannot reproduce the reactivity of thermochromatic ink.

Toner Anchorage

The SuperBusinessCheck paper is treated with toner anchorage that helps bond the toner onto the paper when printed with a hot laser printer. Without toner anchorage, criminals can alter laser checks by lifting off the printing with common office tape. See 'Laser Printing and Check Fraud' in the Abagnale Fraud Bulletin, available through SAFEChecks.

Explicit Warning Bands

The SuperBusinessCheck has two warning banners that explicitly describe specific overt security features and advise the recipient to look for these features before accepting the check. These warning banners may also deter forgers from 'experimenting' with the check.

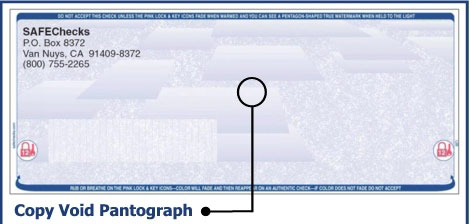

Copy Void Pantograph

This patented security feature is an indiscernible dot pattern designed into the SuperBusinessCheck. When the check is copied or scanned by many copiers, the word 'void' appears and invalidates the copy.

Chemical Sensitivity

The SuperBusinessCheck reacts to over 80 different chemicals. When chemically washed, the SuperBusinessCheck will stain, or discolor and will no longer look like the original document.

Chemical Wash Detection Box

The back of the SuperBusinessCheck contains a box describing the effects of check washing on the check. The check is reactive to over 80 chemicals, and the box may act as a deterrent to chemical tampering.

Prismatic Printing

The design of the SuperBusinessCheck includes an intricate background with subtle gradations between colors. The intricacy and gradations are difficult to reproduce on most color copiers.

High-Resolution Borders

The SuperBusinessCheck is engineered with intricately designed borders that are difficult to duplicate. High-resolution borders are ideal for covert security because the design often distorts when copied.

Chemically Reactive Ink

The dark blue high-resolution borders on the SuperBusinessCheck are made with specially formulated SICPA ink. The borders dissolve when soaked in acetone, showing clear evidence of chemical tampering.

Sequenced Inventory Control Numbers

Every SuperBusinessCheck that is not numbered on the face in the MICR line has a sequenced inventory control number printed on the back. Numbering every check is imperative for audit and control purposes. It discourages internal theft when an accurate log is maintained.

Laid Lines

Lines of varying width and spacing are printed on the back of each SuperBusinessCheck to deter cut-and-paste alterations.

Fluorescent Ink

A security seal and Frank Abagnale's trademarked 'signature' is printed on the back of the check in ultraviolet ink. It becomes visible under ultraviolet light and helps authenticate the original document.

Fluorescent Fibers

The SuperBusinessCheck contains ultraviolet light-sensitive fibers embedded in the paper that fluoresce under UV light and further serve as an authentication tool.

Microprinting

The SuperBusinessCheck contains printing so small that it appears as a line to the human eye, and can only be read with a magnifying glass. Microprinting will often blur when scanned or photocopied.

'Do Not Negotiate' on Back Panel

'Do Not Negotiate' is printed on the back panels of the SuperBusinessCheck stubs. This prevents someone from taking a blank panel and making a fraudulent check on true watermark paper.

Security Features Listed on Back of Check

The SuperBusinessCheck security features are printed on the back panel of each check. This can aid the recipient in knowing which security features to look for in authenticating the check.

Styles and Formats

Laser - Middle

Laser - 3-On-A-Sheet

Pressure Seal

Legal Laser Second Panel

Click Here to Order1. Field of the Invention

Void Pantograph Software

The present invention relates to void pantographs and more particularly, pertains to a method of generating a very large number of different void pantographs.

2. Description of Related Art

Void pantographs (VPs) have been an important part of the security printing industry for quite a while. Void pantographs are traditionally designed for use with a specific printing technology, such as flexo, gravure, offset or screen printing, for example. The designing of VPs for the mobile printing world of today, which involves electro photographic printing methods presents an almost insurmountable problem because of the great variety of printing machines. The present invention provides a method of generating a large, almost limitless, number of different void pantographs, quickly and easily, which can be tested on the printer and copier combination of interest, allowing selection of a VP that works best for that combination.

A large number of different void pantographs are generated for testing with a particular make and model of machine in order to select the void pantograph that works best with a particular make and model machine. The foreground dot patterns are generated by varying the dot size, and dot placement in an x-y grid. The background dot patterns are generated by varying the dot size and dot placement on an x-y grid. By using different combinations of two different dot patterns to generate the foreground patterns and two different dot patterns to generate the background patterns, the number of different pantographs that can be generated is almost limitless.

The exact nature of this invention, as well as the objects and advantages thereof, will become readily apparent from consideration of the following specification in conjunction with the accompanying drawings in which like reference numerals designate like parts throughout the figures thereof and wherein:

FIG. 1 is a pictorial illustration of a computer printing system utilizing the present invention;

FIG. 2 is a graphic illustration of a plurality of pantographs generated by the system of FIG. 1;

Void Pantograph software download, free

FIG. 3 is a graphical depiction of various dot configurations and sizes utilized in the present invention;

FIG. 4 is a graphical representation of the foreground and background patterns and their possible combinations, utilized to generate the void pantographs;

FIG. 5 is a graphical representation of one of the foreground/background pattern combinations of FIG. 4;

FIG. 6 is a graphical representation of an alternate foreground/background pattern selection;

FIG. 7 is a representation of another foreground/background pattern selection;

FIGS. 8A and 8B is a flowchart representing the process by which a pantograph is generated for a specific printer;

FIG. 9 is a graphical representation of a sheet of multiple void pantographs, generated for testing;

FIG. 10 is a graphical representation of the multiple void pantographs of FIG. 9 after being copied;

FIG. 11 is a graphical representation of a void pantograph selected for a particular machine with an interference pattern; and

FIG. 12 is a graphical illustration of the void pantograph of FIG. 11, copied by the machine of interest.

A system 15 having a computer 17, a visual display 18, a printer 19 and a scanner/copier 21 communicating with the processor 17, as illustrated in FIG. 1, is a system that can be used to generate void pantographs.

FIG. 2 is a graphical representation 23 of 130 cells. Each cell contains a different void pantograph generated according to the present invention. The sheet 23 of 130 different void pantographs is divided into 130 cells. One void pantograph occupies each cell. Each cell is identified according to the number of its row 27 and the letter of its column 25. Thus, for example, cell 31 would be identified as cell E9 in test sheet 23. Test sheet 23 is generated by the processor 17 and printed by printer 19, for example. Printer 19 actually prints the void pantograph test sheet 23.

After printing the void pantograph test sheet 23 of 130 cells, for the example, a specific pantograph 31 is identified on the sheet which appears to best hide the 'copy' or other void message. In the example of FIG. 2, the hidden void image is a bold slash extending from top right to bottom left of the cell. This slash is visually apparent in many of the cells on test sheet 23. To determine if pantograph E9 in cell 31 of the test sheet 23 will function adequately in a scanner/copier 21, test sheet 23 is copied by copier 21. FIG. 10 is a copy of printed test sheet 23. Pantograph E9 on test sheet 23 causes a bold slash from the upper right to the lower left to appear when copied.

For specific printers and copiers, pantograph E9 appears to be a good choice. This is not the case in most instances for many of the different other printer models currently on the market.

Each void pantograph, such as the void pantograph in cell 31, consists of a foreground pattern of pixels or dots and a background pattern of pixels or dots. The characters that make up 'copy' text, for example, in a pantograph are printed using the foreground pattern. The background pattern is used simply to print background on a page and hide the foreground text. The combination of the foreground and background patterns hide the characters for the 'copy' text so they are not visible on a printed page when the two patterns visually blend. The characters 'copy' will become visible only when the printed page is copied. FIG. 10 for example, shows a slash from upper right to lower left of a cell after being copied. The slash was not visible in the printed void pantograph with the foreground and background visually blended. The example of a void slash could also be a void 'copy.'

Because different printer models and copier models produce variations in dot patterns, adjustments are required for almost each printer model to come up with a pantograph pattern that works best with that specific printer, copier combination.

This requires a large pool of different pantographs. Both the foreground pattern, which is used to generate the 'copy' characters and the background pattern within which the 'copy' characters are hidden, utilize a constant dot size to produce the patterns. Dot size is one parameter that is varied in order to generate different void pantographs.

Void Pantograph Software

FIG. 3 illustrates various dot sizes that are contemplated for use in the present invention. Dot 33 is a single pixel. Dot 35 is two pixels. Dot 37 is three pixels. Dot 39 is four pixels. Dot 41 is a five pixel dot. The size of the dot is one variable in generating a variety of void pantographs. The spacing of the dots on a grid is another variable used to generate a variety of void pantographs. The dot size and dot spacing variables generate certain foreground and background dot patterns that are combined to form void pantographs.

FIG. 4 graphically illustrates in a narrow subset, to preserve simplicity, a multitude of pattern combinations available for the generation of void pantographs. In one example, the first column 46 illustrates X values. The second column 48 illustrates Y values. The third column 50 illustrates dot size. In a second example, the first column 45 illustrates X values. The second column 47 illustrates Y values. The third column 49, illustrates dot size. The first example illustrates a small subset of patterns available for a four pixel dot with different densities as determined by the 16794377.1 placement of the dots on the X and Y axis. For the first example, the first line shows X, Y and D values of 4, 4, and 4. This indicates a pattern using a four pixel dot size with the dots placed four spaces apart on the X axis and four spaces apart on the Y axis.

The second example illustrates a subset of patterns 43 which has a dot size of three pixels. For purposes of illustration, a foreground and background pattern are chosen from this second subset. Pattern 4, 4, 3 is selected for pattern A, 51 as the foreground pattern. Pattern 9, 4, 3 is selected for pattern B, 53 as the background pattern. The use of these two patterns together produce a void pantograph 55.

The placement of these dots on an X, Y coordinate grid is shown in FIG. 5. Axis 57 is the X axis. Axis 59 is the Y axis. The A pattern is the pattern represented by the round dots 61. The B pattern is the pattern represented by the triangular dots 63. The round dot pattern 61 is considered the foreground pattern, in this example. This pattern would be used to generate the 'copy' characters. The triangular dot pattern 63 is the background pattern, used to hide the 'copy' characters when the background and foreground are combined to generate the void pantograph which is printed on a document.

In order to increase the number of void pantographs available, the present invention contemplates the use of two patterns blended to generate a foreground pattern, and two patterns blended to generate a background pattern. For example, the pattern illustrated in FIG. 4, pattern A51 and pattern B53 could be combined together and used as the foreground pattern of a void pantograph. An alternate combination of pattern A and pattern B would then be needed to form the background pattern of the void pantograph. As can be seen, this increases the number of void pantograph variations available exponentially. For the example of FIG. 2, showing 130 different pantographs, this merging of two different patterns makes 16,900 pantographs available.

FIG. 6 is an illustration of merging two different patterns to form a foreground or background pattern. The double pattern 65 utilizes a three pixel dot with both patterns evenly but differently spaced. This means that the X and Y values are the same within each pattern. The combining of the two patterns creates a double pattern where some of the dots, like dot 67, are separate, some of the dots, like 71, partially overlap, and some of the dots, like dot 67 are closely spaced with other dots.

FIG. 7 illustrates a different combination of two patterns. Here, each pattern has a different dot size. The dot sizes used are dot size 3 and dot size 4. The dots in each pattern are evenly but differently spaced. The combination creates a double pattern 73, where some of the dots, like dot 75 are separate, some of the dots, like dot 79 overlap, and some of the dots, like dot 77, are close together.

The dot patterns 65 and 73, of FIGS. 6 and 7, could be used either as foreground or background patterns to generate a void pantograph. As a starting point for generating a void pantograph, it is contemplated that, a background pattern is selected. The background is kept static while the foreground pattern is varied to generate a variety of pantographs, until a suitable void pantograph is found. Starting with a static foreground pattern and varying the background pattern is equally viable.

Based on experimentation, the inventors have determined that a good starting point for a background pattern is a first pattern with an X-Y spacing of 4, 4 combined with a second pattern having an X-Y spacing of 9, 4. This is the double pattern illustrated in FIG. 5.

Referring now to FIGS. 8A and 8B, a preferred method of generating a void pantograph, according to the present invention, is illustrated. The first step 81 is to select a pantograph message, like 'void,' 'copy' 'X, or '/.' The pantograph message is then sent 82 to be filled with a starting foreground pattern. A foreground pattern 83 is generated and used to fill the pantograph message. Preferably, the foreground pattern is a combination of two different patterns. For example, Pattern A and pattern B, illustrated in FIG. 4, merged together to form a single foreground pattern, illustrated in FIG. 5.

Upon generation of the foreground pattern, multiple background patterns 85 are then produced. These multiple background patterns are also preferably combinations of two of the many subsets of pattern A and pattern B merged together to produce the larger variety of background patterns. The generated foreground pattern and the variety of background patterns are merged 86, to produce a plurality of void pantographs. Before printing the different void pantographs, the void pantographs are classified according to density 89. In other words, lighter pantographs are grouped together, as are darker pantographs. The pantograph cells are printed 90 after being grouped according to like density. The pantographs of similar density 91 are printed to produce a sheet containing a plurality of different void pantographs in separate cells.

The illustration in FIG. 2 shows 130 different void pantographs in 130 individual pantograph cells. All 130 pantographs have a similar density. This test collection of pantograph cells is printed 92 on a sheet of paper by a printer of interest. The printed void pantographs are visually inspected 93 to determine which void pantograph cell has the best visual blending of the foreground pantograph message and the background pattern.

If a desirable void pantograph is not found 96, the process goes back to step 83. With the foreground pattern kept constant, the foreground pattern generated at step 83 is combined with a whole new series of background patterns generated at step 85. In the alternative, rather than changing the background patterns 85, the foreground pattern could be changed at step 83 and combined with the previously generated background pattern. In this manner, an unlimited variety of void pantographs can be generated.

If a void pantograph cell is found at step 93 that acceptably visually blends foreground and background patterns, that cell 94 is evaluated to determine if the pattern is too dark or too light. If the pattern is too dark or too light 100, the process goes back to step 85/83 wherein a new combination of foreground pattern and background patterns generate another test sheet of void pantographs, as shown in FIGS. 2 and 9.

If an acceptable void pantograph cell is found 98, the entire sheet of void pantograph cells is provided to a scanning copier 97, which copies the printed page. The copy of the printed page is examined 102 to determine if the previously selected void pantograph cell shows the 'copy' foreground 99, which was previously hidden.

If the copy provides a clear 'copy' pantograph message 99, it is determined 104 whether the 'copy' message is too light 101. If it should be darker, the process goes back to step 83 to choose a new foreground pattern. If the 'copy' is determined not too light 108, it is assigned to the scanning printer of interest.

1. Field of the Invention

Void Pantograph Software

The present invention relates to void pantographs and more particularly, pertains to a method of generating a very large number of different void pantographs.

2. Description of Related Art

Void pantographs (VPs) have been an important part of the security printing industry for quite a while. Void pantographs are traditionally designed for use with a specific printing technology, such as flexo, gravure, offset or screen printing, for example. The designing of VPs for the mobile printing world of today, which involves electro photographic printing methods presents an almost insurmountable problem because of the great variety of printing machines. The present invention provides a method of generating a large, almost limitless, number of different void pantographs, quickly and easily, which can be tested on the printer and copier combination of interest, allowing selection of a VP that works best for that combination.

A large number of different void pantographs are generated for testing with a particular make and model of machine in order to select the void pantograph that works best with a particular make and model machine. The foreground dot patterns are generated by varying the dot size, and dot placement in an x-y grid. The background dot patterns are generated by varying the dot size and dot placement on an x-y grid. By using different combinations of two different dot patterns to generate the foreground patterns and two different dot patterns to generate the background patterns, the number of different pantographs that can be generated is almost limitless.

The exact nature of this invention, as well as the objects and advantages thereof, will become readily apparent from consideration of the following specification in conjunction with the accompanying drawings in which like reference numerals designate like parts throughout the figures thereof and wherein:

FIG. 1 is a pictorial illustration of a computer printing system utilizing the present invention;

FIG. 2 is a graphic illustration of a plurality of pantographs generated by the system of FIG. 1;

Void Pantograph software download, free

FIG. 3 is a graphical depiction of various dot configurations and sizes utilized in the present invention;

FIG. 4 is a graphical representation of the foreground and background patterns and their possible combinations, utilized to generate the void pantographs;

FIG. 5 is a graphical representation of one of the foreground/background pattern combinations of FIG. 4;

FIG. 6 is a graphical representation of an alternate foreground/background pattern selection;

FIG. 7 is a representation of another foreground/background pattern selection;

FIGS. 8A and 8B is a flowchart representing the process by which a pantograph is generated for a specific printer;

FIG. 9 is a graphical representation of a sheet of multiple void pantographs, generated for testing;

FIG. 10 is a graphical representation of the multiple void pantographs of FIG. 9 after being copied;

FIG. 11 is a graphical representation of a void pantograph selected for a particular machine with an interference pattern; and

FIG. 12 is a graphical illustration of the void pantograph of FIG. 11, copied by the machine of interest.

A system 15 having a computer 17, a visual display 18, a printer 19 and a scanner/copier 21 communicating with the processor 17, as illustrated in FIG. 1, is a system that can be used to generate void pantographs.

FIG. 2 is a graphical representation 23 of 130 cells. Each cell contains a different void pantograph generated according to the present invention. The sheet 23 of 130 different void pantographs is divided into 130 cells. One void pantograph occupies each cell. Each cell is identified according to the number of its row 27 and the letter of its column 25. Thus, for example, cell 31 would be identified as cell E9 in test sheet 23. Test sheet 23 is generated by the processor 17 and printed by printer 19, for example. Printer 19 actually prints the void pantograph test sheet 23.

After printing the void pantograph test sheet 23 of 130 cells, for the example, a specific pantograph 31 is identified on the sheet which appears to best hide the 'copy' or other void message. In the example of FIG. 2, the hidden void image is a bold slash extending from top right to bottom left of the cell. This slash is visually apparent in many of the cells on test sheet 23. To determine if pantograph E9 in cell 31 of the test sheet 23 will function adequately in a scanner/copier 21, test sheet 23 is copied by copier 21. FIG. 10 is a copy of printed test sheet 23. Pantograph E9 on test sheet 23 causes a bold slash from the upper right to the lower left to appear when copied.

For specific printers and copiers, pantograph E9 appears to be a good choice. This is not the case in most instances for many of the different other printer models currently on the market.

Each void pantograph, such as the void pantograph in cell 31, consists of a foreground pattern of pixels or dots and a background pattern of pixels or dots. The characters that make up 'copy' text, for example, in a pantograph are printed using the foreground pattern. The background pattern is used simply to print background on a page and hide the foreground text. The combination of the foreground and background patterns hide the characters for the 'copy' text so they are not visible on a printed page when the two patterns visually blend. The characters 'copy' will become visible only when the printed page is copied. FIG. 10 for example, shows a slash from upper right to lower left of a cell after being copied. The slash was not visible in the printed void pantograph with the foreground and background visually blended. The example of a void slash could also be a void 'copy.'

Because different printer models and copier models produce variations in dot patterns, adjustments are required for almost each printer model to come up with a pantograph pattern that works best with that specific printer, copier combination.

This requires a large pool of different pantographs. Both the foreground pattern, which is used to generate the 'copy' characters and the background pattern within which the 'copy' characters are hidden, utilize a constant dot size to produce the patterns. Dot size is one parameter that is varied in order to generate different void pantographs.

Void Pantograph Software

FIG. 3 illustrates various dot sizes that are contemplated for use in the present invention. Dot 33 is a single pixel. Dot 35 is two pixels. Dot 37 is three pixels. Dot 39 is four pixels. Dot 41 is a five pixel dot. The size of the dot is one variable in generating a variety of void pantographs. The spacing of the dots on a grid is another variable used to generate a variety of void pantographs. The dot size and dot spacing variables generate certain foreground and background dot patterns that are combined to form void pantographs.

FIG. 4 graphically illustrates in a narrow subset, to preserve simplicity, a multitude of pattern combinations available for the generation of void pantographs. In one example, the first column 46 illustrates X values. The second column 48 illustrates Y values. The third column 50 illustrates dot size. In a second example, the first column 45 illustrates X values. The second column 47 illustrates Y values. The third column 49, illustrates dot size. The first example illustrates a small subset of patterns available for a four pixel dot with different densities as determined by the 16794377.1 placement of the dots on the X and Y axis. For the first example, the first line shows X, Y and D values of 4, 4, and 4. This indicates a pattern using a four pixel dot size with the dots placed four spaces apart on the X axis and four spaces apart on the Y axis.

The second example illustrates a subset of patterns 43 which has a dot size of three pixels. For purposes of illustration, a foreground and background pattern are chosen from this second subset. Pattern 4, 4, 3 is selected for pattern A, 51 as the foreground pattern. Pattern 9, 4, 3 is selected for pattern B, 53 as the background pattern. The use of these two patterns together produce a void pantograph 55.

The placement of these dots on an X, Y coordinate grid is shown in FIG. 5. Axis 57 is the X axis. Axis 59 is the Y axis. The A pattern is the pattern represented by the round dots 61. The B pattern is the pattern represented by the triangular dots 63. The round dot pattern 61 is considered the foreground pattern, in this example. This pattern would be used to generate the 'copy' characters. The triangular dot pattern 63 is the background pattern, used to hide the 'copy' characters when the background and foreground are combined to generate the void pantograph which is printed on a document.

In order to increase the number of void pantographs available, the present invention contemplates the use of two patterns blended to generate a foreground pattern, and two patterns blended to generate a background pattern. For example, the pattern illustrated in FIG. 4, pattern A51 and pattern B53 could be combined together and used as the foreground pattern of a void pantograph. An alternate combination of pattern A and pattern B would then be needed to form the background pattern of the void pantograph. As can be seen, this increases the number of void pantograph variations available exponentially. For the example of FIG. 2, showing 130 different pantographs, this merging of two different patterns makes 16,900 pantographs available.

FIG. 6 is an illustration of merging two different patterns to form a foreground or background pattern. The double pattern 65 utilizes a three pixel dot with both patterns evenly but differently spaced. This means that the X and Y values are the same within each pattern. The combining of the two patterns creates a double pattern where some of the dots, like dot 67, are separate, some of the dots, like 71, partially overlap, and some of the dots, like dot 67 are closely spaced with other dots.

FIG. 7 illustrates a different combination of two patterns. Here, each pattern has a different dot size. The dot sizes used are dot size 3 and dot size 4. The dots in each pattern are evenly but differently spaced. The combination creates a double pattern 73, where some of the dots, like dot 75 are separate, some of the dots, like dot 79 overlap, and some of the dots, like dot 77, are close together.

The dot patterns 65 and 73, of FIGS. 6 and 7, could be used either as foreground or background patterns to generate a void pantograph. As a starting point for generating a void pantograph, it is contemplated that, a background pattern is selected. The background is kept static while the foreground pattern is varied to generate a variety of pantographs, until a suitable void pantograph is found. Starting with a static foreground pattern and varying the background pattern is equally viable.

Based on experimentation, the inventors have determined that a good starting point for a background pattern is a first pattern with an X-Y spacing of 4, 4 combined with a second pattern having an X-Y spacing of 9, 4. This is the double pattern illustrated in FIG. 5.

Referring now to FIGS. 8A and 8B, a preferred method of generating a void pantograph, according to the present invention, is illustrated. The first step 81 is to select a pantograph message, like 'void,' 'copy' 'X, or '/.' The pantograph message is then sent 82 to be filled with a starting foreground pattern. A foreground pattern 83 is generated and used to fill the pantograph message. Preferably, the foreground pattern is a combination of two different patterns. For example, Pattern A and pattern B, illustrated in FIG. 4, merged together to form a single foreground pattern, illustrated in FIG. 5.

Upon generation of the foreground pattern, multiple background patterns 85 are then produced. These multiple background patterns are also preferably combinations of two of the many subsets of pattern A and pattern B merged together to produce the larger variety of background patterns. The generated foreground pattern and the variety of background patterns are merged 86, to produce a plurality of void pantographs. Before printing the different void pantographs, the void pantographs are classified according to density 89. In other words, lighter pantographs are grouped together, as are darker pantographs. The pantograph cells are printed 90 after being grouped according to like density. The pantographs of similar density 91 are printed to produce a sheet containing a plurality of different void pantographs in separate cells.

The illustration in FIG. 2 shows 130 different void pantographs in 130 individual pantograph cells. All 130 pantographs have a similar density. This test collection of pantograph cells is printed 92 on a sheet of paper by a printer of interest. The printed void pantographs are visually inspected 93 to determine which void pantograph cell has the best visual blending of the foreground pantograph message and the background pattern.

If a desirable void pantograph is not found 96, the process goes back to step 83. With the foreground pattern kept constant, the foreground pattern generated at step 83 is combined with a whole new series of background patterns generated at step 85. In the alternative, rather than changing the background patterns 85, the foreground pattern could be changed at step 83 and combined with the previously generated background pattern. In this manner, an unlimited variety of void pantographs can be generated.

If a void pantograph cell is found at step 93 that acceptably visually blends foreground and background patterns, that cell 94 is evaluated to determine if the pattern is too dark or too light. If the pattern is too dark or too light 100, the process goes back to step 85/83 wherein a new combination of foreground pattern and background patterns generate another test sheet of void pantographs, as shown in FIGS. 2 and 9.

If an acceptable void pantograph cell is found 98, the entire sheet of void pantograph cells is provided to a scanning copier 97, which copies the printed page. The copy of the printed page is examined 102 to determine if the previously selected void pantograph cell shows the 'copy' foreground 99, which was previously hidden.

If the copy provides a clear 'copy' pantograph message 99, it is determined 104 whether the 'copy' message is too light 101. If it should be darker, the process goes back to step 83 to choose a new foreground pattern. If the 'copy' is determined not too light 108, it is assigned to the scanning printer of interest.

An example of this process is shown in FIGS. 9-12. FIG. 9 shows a page of printed void pantograph cells, created by the process of the present invention, as showing an appropriate or sufficient blending of the background and foreground patterns. The foreground pattern, in the form of a stripe going from upper right to lower left is sufficiently blended.

FIG. 10 illustrates the page of void pantographs of FIG. 9 copied by a scanning copier, which causes the foreground pattern stripe to show up. With respect to the selected void pantograph cell D9 (FIGS. 9 and 10), the stripe appears to be quite distinctive after copying. Not too light, and therefore, acceptable. The void pantograph D9 would then be assigned to the scanning printer that copied the printed void pantograph cells of FIG. 9.

FIG. 11 illustrates the use of an overlay interference pattern, which happens to be a mortar and pestle design, used predominately for prescription paper. This pattern is overlaid onto a selected void pantograph. As can be seen from FIG. 11, no pantograph message is apparent. Any differences between the foreground and background pattern of the void pantograph are successfully masked by the overlay interference pattern.

When this void pantograph, with the interference overlay, is copied, as shown in FIG. 12, the pantograph message 'copy' clearly shows up, indicating that this is not an original document.